3D printing is one of the new technologies that everyone knows about and has heard of at some point, and which can be used to build almost any type of object. 3D printing in construction is already here, it is here to stay, and it is something that can revolutionise this sector.

Will it have a future?

What is 3D printing?

3D printing in construction makes it possible to create a three-dimensional object by superimposing several successive layers of material. It is a very versatile construction method and is capable of generating from specific elements to complex structures such as living spaces or houses, modular structures, walls, offices, bridges, urban furniture, decorative elements or any type of object.

What can be made with a 3D printer?

Its design process is computer-based. Through BIM or CAD software, a 3D printer receives all the necessary information to “print” and starts to superimpose the different materials according to the design indications to generate all kinds of objects.

How does 3D printing work in construction?

Layer by layer, the structure is built with millimetric precision, including the reinforcement of the walls and everything necessary to achieve a finished house, right down to the pipes for the different installations. Once finished, it is moved to the chosen location and placed on its foundations.

In this way, it is possible to build a house of about 100 m2 in a period of two and a half months, whereas the same house built by the traditional method would take between 7 and 12 months.

Benefits of 3D printing in construction

The advantages of this construction method are numerous with respect to those executed on site. We have identified some of the most relevant ones:

- Time savings of around 70%.

- More sustainable and environmentally friendly method (due to the materials used and the reduction of waste).

- Safer (there are hardly any accidents at work).

- Flexibility in its design.

What are the disadvantages of 3D printing?

But despite all the advantages we have highlighted, there are still many challenges that need to be overcome for real estate 3D printing to achieve wider market adoption. Here are some of the points that we believe still need to be improved:

- Although the cost of a house built by 3D printing is cheaper than a traditional one, the machinery needed for its construction is still quite expensive, both for its acquisition and its operation.

- This industry requires a high level of training for professionals to handle the technology involved. At present, there is little training in this area.

- Current legislation and regulation of 3D printing is not as developed as it should be. It is necessary to establish clear guidelines on its implementation in order to benefit from all the advantages of this construction technique.

Techniques and types of 3D printing for construction

Extrusion is the most common 3D printing technique, as it can be used in almost any environment. This method creates an object by layering material through one or more nozzles mounted on a movable support. The most commonly used extrusion mounts for 3D printing in construction are:

- Robotic arm: Automatically controlled printer that allows freedom of movement and flexibility to programme multiple tasks. The arm is capable of printing from multiple angles, allowing the realisation of complex geometries and curves, and allows printing in larger sizes compared to other 3D printing methods.

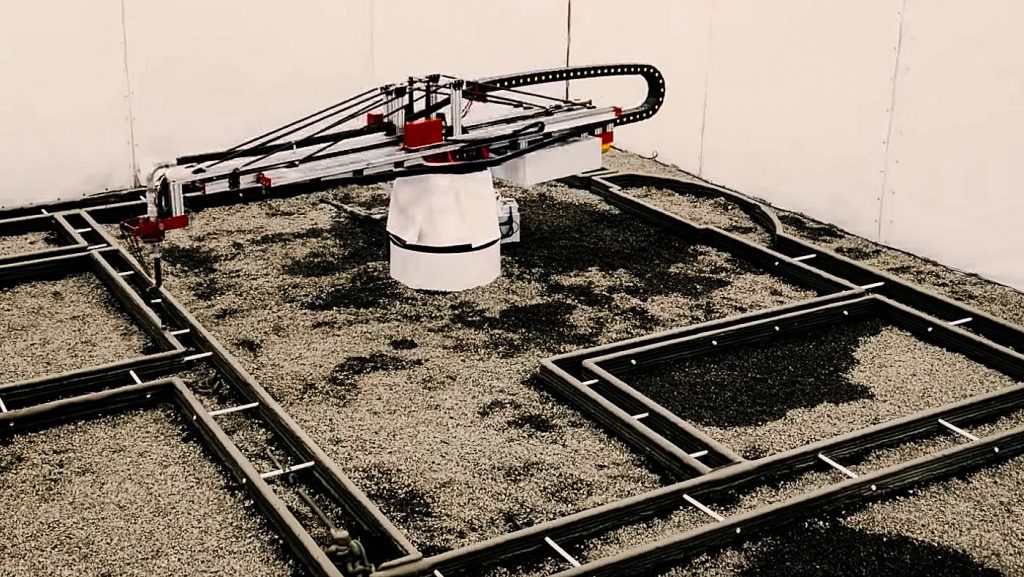

- Gantry system: The contouring method marks the beginning of 3D printing in construction. This process deposits building material to form a 3D model and create large-scale structures with a smooth surface finish. It works by means of rails placed around the floor of the building that act as a guide to direct the robotic arm in applying the concrete layer by layer.

Other 3D printing techniques and types

There are several technologies that are available for 3D printing. They differ in the different ways in which the material is treated to create parts. The most prominent methods are:

- Injection printing: The printer spreads a layer on the section of the part to be formed. The process is repeated until all the layers are printed and is the only one that allows colour printing.

- Fused Deposition Modelling (FDM): This method consists of depositing a molten material layer by layer on a structure to solidify it by means of a laser.

- Photopolymerisation by ultraviolet light (SGC): This consists of exposing a container of liquid polymer to light. This hardens and solidifies, creating the different layers.

- Stereolithography: This is the use of photopolymeric liquid resins that solidify thanks to the use of an ultraviolet laser. It is used for the production of patterns, models and definitive parts.

- Photopolymerisation by photon absorption (SLS): The 3D object is created using a block of gel and a laser. This solidifies the gel in the modelling and is a technique widely used for printing small details.

- Ice printing: It uses ice as a material and is a technique that is still in the experimental phase.

The future of 3D printing in construction

The possibility of building houses in a short space of time, together with the growing concern we have for preserving our environment, are sufficient reasons to encourage companies to take an interest in the use of 3D printing in construction.

The future of construction depends on the use of ecological, organic and recyclable materials, together with a reduction in the production of waste and an increase in the safety conditions of workers to reduce accidents at work.

And if to all of the above we add the possibility for the user to fully customise their future home, from its materials to its design and characteristics, there is no doubt that 3D printing will be responsible for the future homes of generations to come.

As you can see, 3D printing in construction is a technique that, if it gets the right development, could bring numerous benefits and will be responsible for the houses of the future. Can you imagine what our cities will be like because of it?