At Alubuild, we shape your vision

Buildbond panels are manufactured through a continuous process and each product has detailed traceability.

In addition to manufacturing aluminium composite panels, Alubuild also offers a machining service to adapt its products to the specific needs of each project.

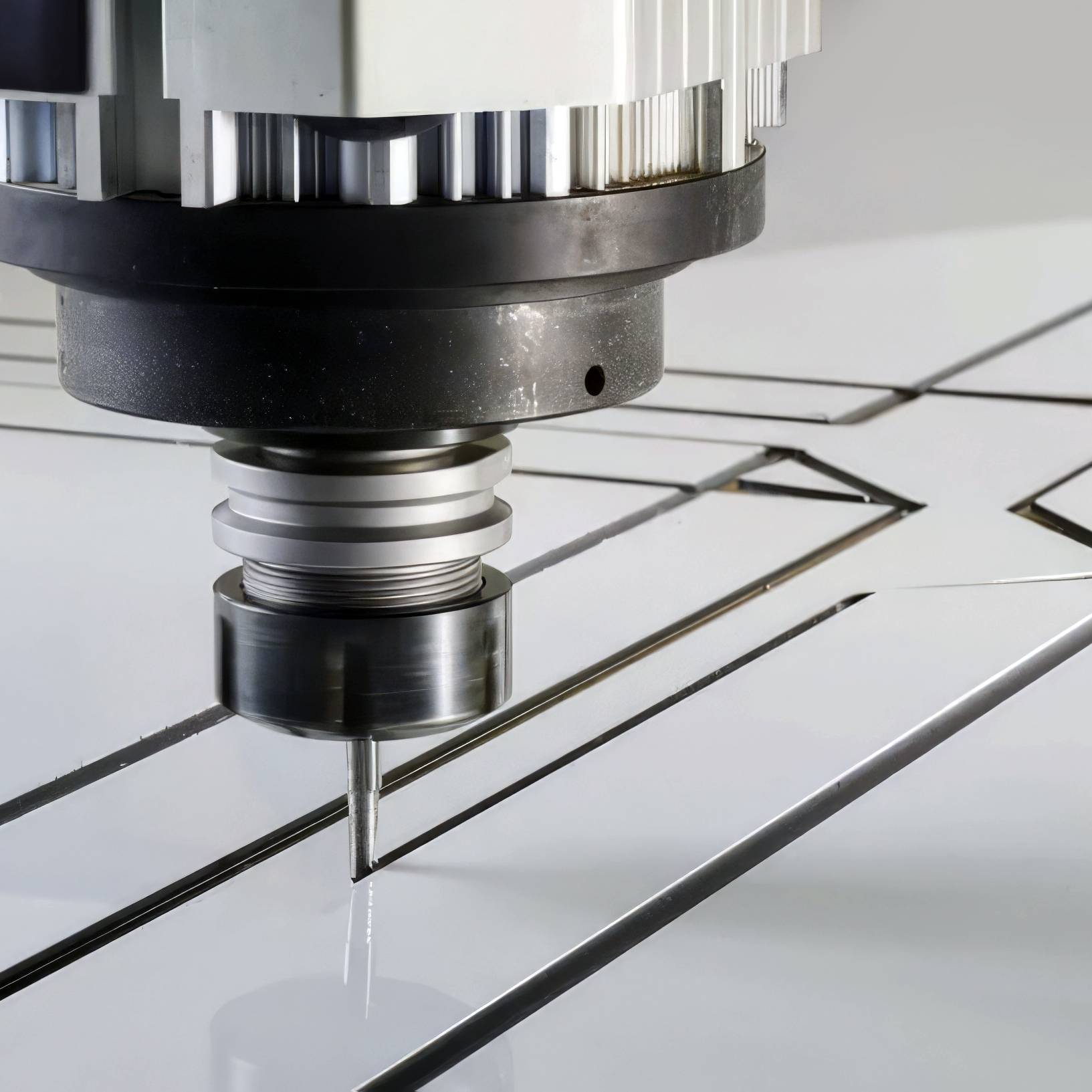

Alubuild‘s machining service includes a wide range of processes and has a team of qualified and experienced professionals who use the latest technology to guarantee a high-quality finish.

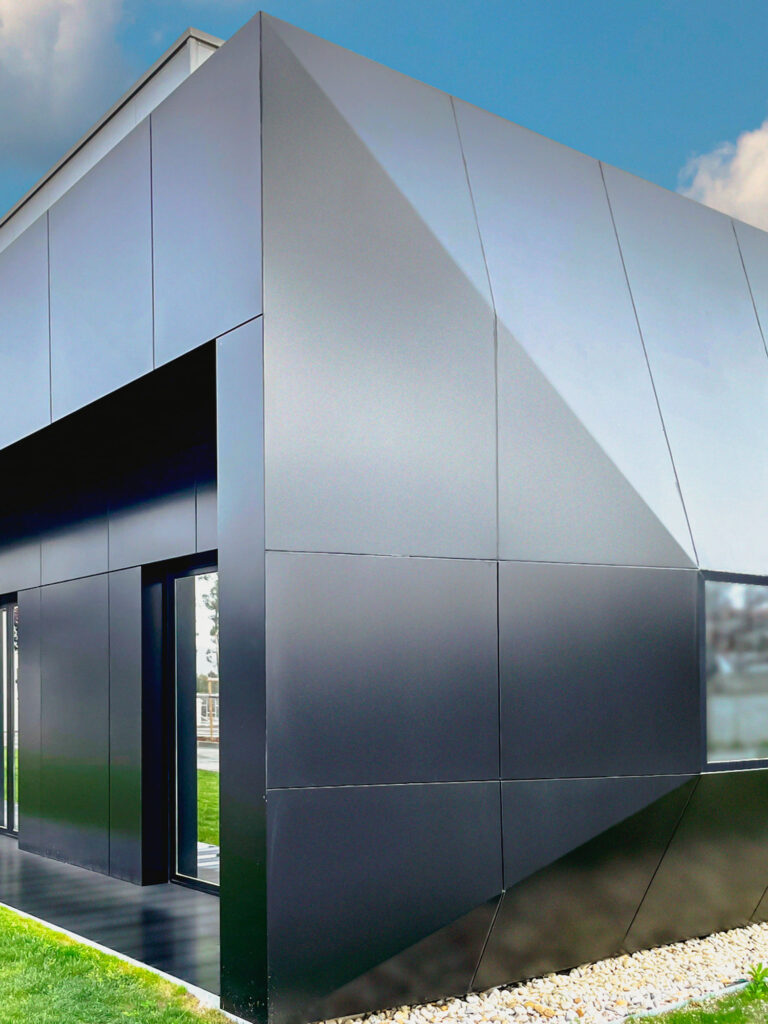

Aluminium composite panel is a versatile and resistant material used in a wide variety of applications, such as façades, cladding, signage, etc. Alubuild‘s machining service makes it possible to adapt these panels to any requirement, from small decorative details to large structures.

Processes

Cutting

Bending

Edge folding

Roller-bending

Milling

Drilling

Punching

Embossing

Riveting

Precision moulding

Buildbond composite panels can be precisely adapted to any type of building, finding the shapes designed by architects from flat, 3D, curved, perforated or stamped, giving the desired aesthetic finish.

Endless possibilities

Alubuild has a state-of-the-art CNC machining centre, bending machine, splicer and punching machine, which allows us to create precise and complex aesthetic shapes to generate the desired aesthetic finish.

Inspiring shapes

Alubuild can manufacture large format panels up to 2 metres wide, allowing it to work in collaboration with architectural studios looking for the best solutions for their façade.